This saves costs consequently along the entire manufacturing route.

#MAGMASOFT PRICING SOFTWARE#

The software supports the user in the modeling of the component, the determination of melting practice and casting methoding through to model and mold making, heat treatment, and finishing. The range of application of MAGMA solutions comprises all cast alloys, from cast iron to aluminum sand casting, permanent mold and die casting up to large steel castings. MAGMA5 consists of a base module and a set of additional modules that cover all steps of the casting production. MAGMA stands for robust and innovative casting solutions as well as a strong partnership with the metal casting industry.

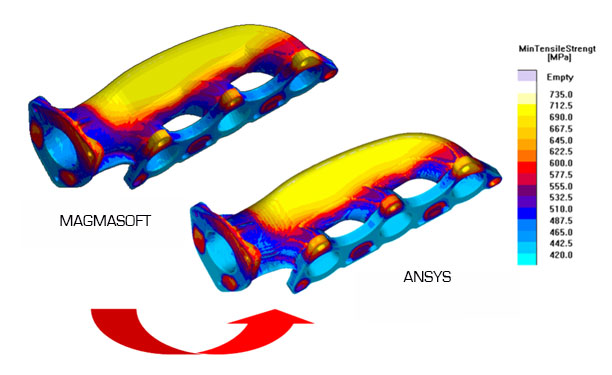

This not only results in a reduction in pre-production sampling as the precise layout of the complete casting system leads to energy, material, and tooling savings. Magmasoft Magma 5.2 54 magma magmasoft, magmasoft magma 5MAGMA presents with the latest software version MAGMASOFT 5.4, a comprehensive toolbox of new capabilities for the optimiz Return to site Download. Simulation accurately describes a cast component's quality up-front before production starts and the casting methoding can be designed with respect to the required component properties. Simulating the casting process has helped Spokane support their selling point that they are on the cutting edge of the industry. With the addition of MAGMA ® casting simulation software, Denison now has the capability to model (using Pro-Engineer ®) and analyze cast parts to provide comprehensive filling and solidification analyses to customers. Customers come to Spokane Industries’ steel foundry not just to buy castings, but to find solutions to their problems. MAGMAsoft® is Denison Industries’ comprehensive simulation tool for the technological and quality-focused production of your castings. The software stands for the prediction of the entire casting component quality and process chain by providing a better understanding of mold filling, solidification and cooling and allows the quantitative prediction of mechanical properties, thermal stresses and distortions of the resulting castings. Casting Process Simulation Provides Cost Effective Solutions. MAGMA5 is the standard solution for the simulation of casting processes. ( October 2015) ( Learn how and when to remove this template message)

Please help improve it by removing promotional content and inappropriate external links, and by adding encyclopedic content written from a neutral point of view. none MAGMA’s range of products and services includes the simulation software MAGMASOFT ® autonomous engineering, for virtual designs of experiments and autonomous optimization of casting processes, as well as comprehensive engineering services for casting design and process optimization. With additional collaboration features like chatting, everyone can get involved in the process.

MAGMA’s product portfolio based on Autonomous Engineering leads to robust and cost effective solutions in component design, tooling lay-out and production. With Magma Studio, you can work on one drawing at the same time with as many as 30 people. MAGMA stands for robust and innovative casting solutions as well as a strong partnership with the metal casting industry. This section contains content that is written like an advertisement. Two heads are better than one and a real team-based creative process can take your art to the next level.

0 kommentar(er)

0 kommentar(er)